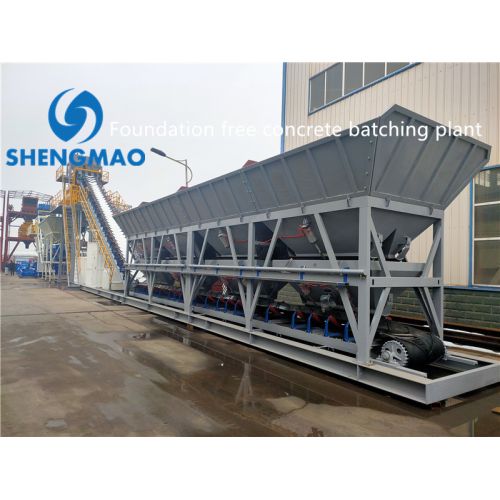

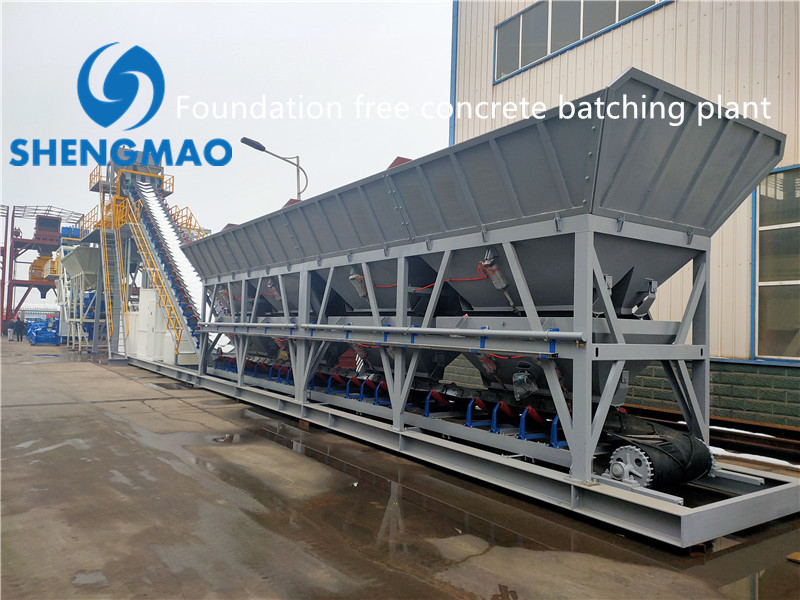

Foundation Free Concrete Batching Plant

For each part of foundation free concrete batching plant, there is a steel base. We just need to make sure the job site ground is hard and dry, we can place the machine on the ground and start to work directly.

Product Description

For each part of foundation free concrete batching plant, there is a steel base. We just need to make sure the job site ground is hard and dry, we can place the machine on the ground and start to work directly. In this way, we can save much time and cost to make reinforced concrete foundation. And it is also very easy to disassemble and move to another job site.

1. what is a foundation free concrete batching plant?

1) Foundation free concrete batching plant is a concrete batching plant that we don't need to make huge reinforced concrete foundation. Usually, we can save about 20 days to make the foundation and about 50 cubic meters of concrete (for a medium-sized concrete batching plant). Although we don't need to make concrete foundation, we still need to make sure the ground is flat, dry and hard so that we can place the foundation free concrete batching plant on the ground to use.

2. Advantages of a foundation free concrete batching plant.

1) Quick installation. Because we don't need to make a huge concrete foundation, we can finish the installation quickly. Usually, we can save about 60% time needed for the installation of a traditional concrete batching plant.

2) Easy to move to other work sites;

3) Compact design which is suitable for transporation with containers;

4) Compulsory twin-shaft mixer is used to make sure the quality of the concrete.

3. Components of our foundation free concrete batching plant.

1) Aggregate batching machine with steel base;

2) Aggregate loading belt conveyor or skip hoist;

3) Water, cement and additive scales;

4) Concrete mixer: twin-shaft mixer or planetary mixer;

5) Cement silo: traditional vertical cement silo or horizontal cement silo. Horizontal cement silo is more and more popular because it is very easy to install and no needs foundation;

6) Screw conveyor;

7) Control system.