Cooling Tower Filler

The cooling tower is a cooling device, which makes the hot water in the tower be cooled mainly by the evaporative cooling of water. In order to make full use of water resources, reduce the load of urban tap water supply network, and reduce the operating cost, cooling water is treated by cooling tower and recycled.

Product Description

Cooling Tower Fill VF610-LC introduction

The cooling tower is a cooling device, which makes the hot water in the tower be cooled mainly by the evaporative cooling of water. In order to make full use of water resources, reduce the load of urban tap water supply network, and reduce the operating cost, cooling water is treated by cooling tower and recycled.

“Fill” is a medium that used in cooling towers to increase the surface area available for the water.

In a cooling tower, the really important actually is cooling tower fill. Fill is a plastic sheet used in cooling towers to build the more surface region of the tower. If we want to expanded surface, we need to take considers into making more contact about water and fills, so that water will have more surface area in the cooling tower fill.

Cooling tower fills make hot water have much more surface area with sheet and air and the medium of tremendously extended film fill, so that hot water is cooled quickly.

After be cooled the water is flow in a water container from which it is pumped again to cooling other hot water, and the warm air leaving the fill and releasing from the above of the cooling towers ,and like this Continuously cooling air from bottom and release warm air from above to keep cooling tower cooling hot water continuously, to reduce the load of urban tap water supply network, and reduce the operating cost, So that we could make full use of water resources.

Filler is the most important part of the cooling tower, and its efficiency depends on the extent to which the cooling water and air are fully in contact with the filler. Filler temperature 50 °C ~ 68 °C, anti-aging, excellent performance, anti-ultraviolet, long life.

Cooling tower fill should be made to have more contact about water and fills , and longest time as possible. Fill allows the water to form thin flowing sheets to expose as much water surface area as possible to the interacting flow.

Cooling Tower Fill VF610-LC Specification

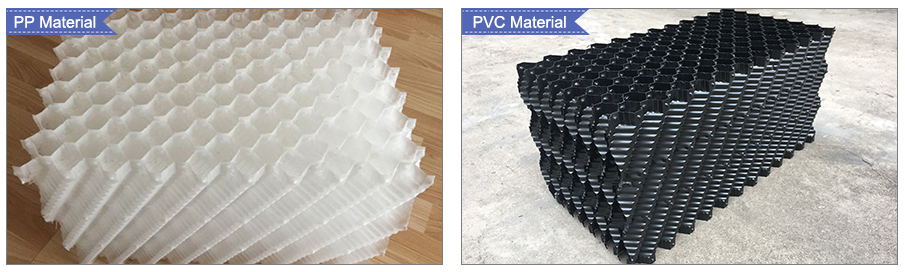

| Type | VF610-LC |

| Material | PP/PVC |

| Width | 305mm |

| Length | as your request |

| Thickness | from 0.28mm to 0.38mm |

| Sheet Space | 19mm |

| Application |

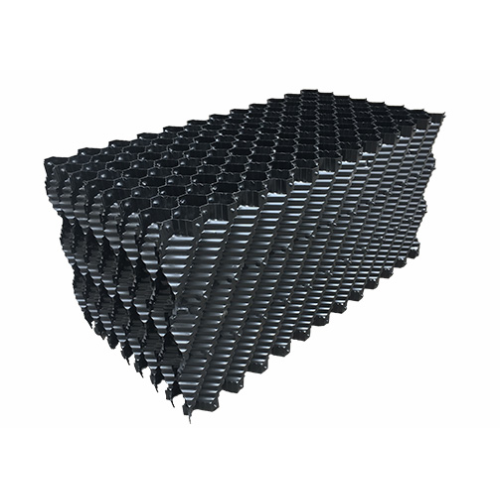

Cooling Tower Fill Display

How to choose Cooling Tower fill?

Both splash and film fill are ideal for facilitating the evaporation and cooling process in a cooling tower. However, film fill media is more efficient in heat transfer as it creates a larger surface area, hence optimized performance. However, it is more susceptible to wear and tear due to constant exposure to water at very high temperatures.

If your cooling tower applications involve recirculating water with poor quality and high solids content, you may opt for splash fill media for better performance. Also, if water is generated at very high temperatures, you may consider splash fill media with metallic bars as film fill media will wear away prematurely.

Cooling towers are essential equipment in most manufacturing industries. With this knowledge, you can choose the right type of tower fill media for optimal performance and improved efficiency of your industry's cooling tower.

The cooling tower is the main core of heat dissipation for circulating water in industrial production. In China's industrial production, it affects the cost and efficiency of industrial production in China.

Inappropriate use of cooling towers in industrial production can result in inefficient heat dissipation, production stagnation, and high water temperature risk. Cooling tower packing is the main factor that promotes hydrothermal cycle. Therefore, we must choose high-quality cooling tower fill.

♦ First, the cross-flow cooling tower standard size.

The distance between the top of the cooling tower packing and the bottom of the fan should be 1.2 times the diameter of the fan.

♦ Second, counterflow cooling tower standard angle.

1. When constructing a counterflow cooling tower, the top of the packing and the airflow section should be controlled within 90 degrees. A flat top cover is used and a diversion coil is installed. The water eliminator and the airflow section are angled at 90-120 degrees. between.

2. Shrink-type tower top, the top corner of the shrinkage section cover should be controlled between 90-110 degrees.

3. the water filling angle is controlled between 5-8 degrees.

4. In the process of use, spare circulation measures should be set in order to prevent short circuit between the air and the bottom of the packing.

In cold regions, we must choose a special filler material, according to the local temperature is determined, select the filler with high cold resistance. The heat and resistance of the cooling tower packing should be based on comprehensive analysis of the fan. Through the calculation, design a suitable cooling tower infill.

Welcome to Long Zhuo

Long Zhuo products mainly include Cooling Tower Accessories (such as Cooling Tower Fill, Drift Eliminator, Mist Eliminator, Spray Nozzle etc.) Water Treatment Media (such as Tube Settler, MBBR Media, Bio Ball Media, Diffusion Aerator etc.) and Water Tank (such as GRP Water Tank, Galvanized Steel Water Tank, Stainless Steel Water Tank). All of the products support OEM.

If you need, click here:

sales@coolingtowerinfill.com

admin@longzhuochn.com