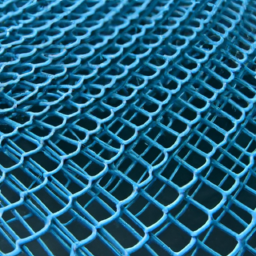

Hot Dip Galvanized Cable Tray

Metal cable trunking or perforated cable tray is a more reliable, less expensive solution for supporting and protecting cables. Handling, lifting anf fitting operations are inherently safer, easier and quicker.

Product Description

Metal cable trunking or perforated cable tray is a more reliable, less expensive solution for supporting and protecting cables. Handling, lifting anf fitting operations are inherently safer, easier and quicker.

In the development of our cable trunking systems we always opt for high-quality metals in combination with a well-thought-out system consisting of various accessory fittings, useful accessories and coordinated fastenings. This guarantees you a high level of flexibility and efficiency in the design of your individual trunking layout – and of course maximum protection for your cable installation. Thanks to the specific strengths of each different cable trunking system, we can offer you the perfect solution for your cable routing, regardless of whether you need to route a large number of cables over long distances, a small number of cables in limited installation space or cables for hygienic applications.

Prouduct Parameters

| Material | Surface finish | Thickness of coating | Short | Application enviroument |

| Mediun Carbon steel | Zinc coating | >12μm | EZ | Indoor |

| Powder coating | >60μm | PC | Indoor.need color | |

| Hot dip galvanized | >60μm | HDG | Ourtdoor, Indoor | |

| Pre-galvanized steel | 7-8μm | GI | Indoor | |

| Nickel coating | / | Ni | Indoor, Uutdoor | |

| Stainless steel SS304 | Acid washing+polishing(option) | N/A | SS304 | Outdoor, Indoor |

| Stainless steel SS316L | Acid washing+polishing(option) | N/A |

SS316L |

High corrosion occasions |

| Aluminum alloy | Acid washing+polishing(option) | N/A | Al alloy | High corrosion occasions |

Prouduct Features

1. Good reliability: the zinc coating and the steel are metallurgically combined and become a part of the steel surface, so the durability of the coating is relatively reliable;

2. Low treatment cost: the cost of hot-dip galvanizing is lower than that of other paint coatings;

3. Durable: In the suburban environment, the standard hot-dip galvanized anti-rust thickness can be maintained for more than 50 years without repair; In urban or offshore areas, the standard hot-dip galvanized antirust coating can be maintained for 20 years without repair;

4. Low initial cost: Generally, the cost of hot-dip galvanizing is lower than that of other protective coatings. The reason is very simple. Other protective coatings, such as sanding and painting, are labor-intensive processes. On the contrary, the hot-dip galvanizing process is highly mechanized and tightly controlled in-plant construction.

5. The toughness of the coating is strong: the galvanized coating forms a special metallurgical structure, which can withstand mechanical damage during transportation and use;

6. Reliability: The specification of hot-dip galvanizing is generally in accordance with BS EN ISO 1461, which limits the thickness of its zinc layer, so its anti-rust period and performance are reliable and predictable.

7. Comprehensive protection: every part of the plated part can be coated with zinc, and can be fully protected even at the depression, sharp corner and hidden place;

8. Save time and effort: the galvanizing process is faster than other coating construction methods, and can avoid the time required for painting on the site after installation.

9. The inspection is simple and convenient: the hot-dip zinc coating can be tested by visual inspection and simple non-destructive coating thickness table.

Email: stellalee@hbcn-solucent.com

Mob.: +86 13393212615

Tel.: +86 0311-85861210

WeChat: +86 13393212615

Whatsapp: +8613393212615

Add.: No. 8 Kangle Street, Xinhua District, Shijiazhuang City, Hebei Province, China