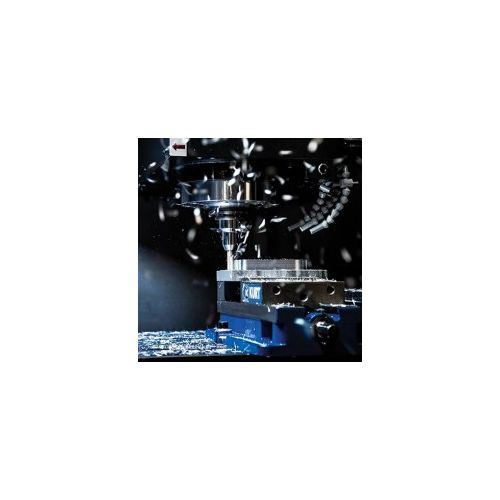

CNC machining for high-volume production

CNC machining for high-volume production

Product Description

Advantages of High Volume CNC Machining with GD HUB

CNC Machining offers a multitude of benefits that are critical for businesses operating at scale:

◆ Fast Machining Speed: GD HUB's advanced CNC machines ensure rapid production cycles, significantly reducing the time to market for your products.

◆ Consistent Quality: Automated processes guarantee uniformity in every component, eliminating the human error factor typical of manual machining.

◆ Scalability: Easily adjust production volumes to align with fluctuating demands without affecting efficiency or quality.

◆ Reduced Lead Time: Streamlined operations and optimized tool paths shorten production timelines, ensuring swift delivery.

◆ Overall Cost Savings: Minimized labor and material waste result in cost-effective production runs, benefiting both the company and the customer.

Applications of High Volume CNC Machining

The applications for high volume machining are extensive and cross various industries:

◆ Automotive Industry: Precision components for engines, transmissions, and other systems.

◆ Aerospace Industry: Critical parts for aircraft engines, landing gear, and avionics.

◆ Electronics: Miniaturized parts for connectors, heat sinks, and electronic enclosures.

◆ Medical Industry: Devices and components like surgical instruments and implants.

◆ Industrial Applications: Machinery parts, automation components, and tooling.

◆ Consumer Electronics: Components for smartphones, laptops, and gaming consoles.

◆ Energy and Power Generation: Parts for turbines, generators, and renewable energy equipment.