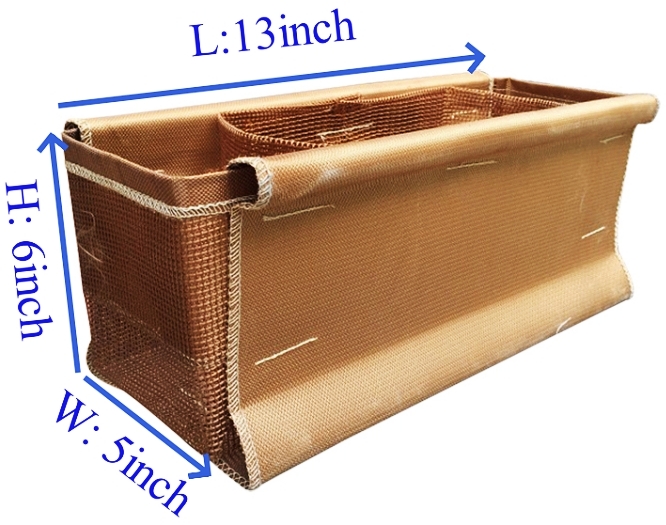

Foundry Filtration Bag Pouch For Molten Metal

Fiberglass Filtration & Shunt Combo bag is weaved by special high-twist & high-strength alkali-free fiberglass yarn, special post-treatment, coated with phenolic resin and suitable "carbonized" by high temperature.

Product Description

Fiberglass Filtration & Shunt Combo bag is weaved by special high-twist & high-strength alkali-free fiberglass yarn, special post-treatment, coated with phenolic resin and suitable "carbonized" by high temperature.

Features:

● New environmental protection material, does not burn during whole use process , no harm to human body.

● Advanced production equipment, warp and weft standard for base cloth, high temperature resistant coating mesh uniform, the finished product is exquisitely made without burrs.

● Both sides of the bag adopt square hole fixing device technology, more convenient operation and improve the working rate.

● Comparing to other filter bags, it does not affect the component of aluminum alloy, and with good filtration effect, high temperature resistance, high strength, excellent acid and alkali resistance, non-stick aluminum, non-slagging, non-peeling, as well as easy installation.

| Type | Fiberglass Filtration & Shunt Combo Bag For Aluminum |

| Work Temperature | ≤1000℃ |

| Melting Point | 1100℃ |

| Color | White, Brown and Yellow |

| Normal Dimensions | 120x150x300mm, 120x150x330mm, 140x150x450mm, |

| Mesh Openning | 5mesh, 7mesh, 8mesh, 9mesh, 10mesh, 12mesh, 14mesh, 16mesh, 18mesh, 20mesh, 25mesh, and special specifications can be customized. |

| Application | Filtration & Shunt For All Aluminium and aluminium alloy products. |

| Work Time: | 4hours when flow ≤10 kg/min. |

| 1.5hours when flow ≤120 kg/min. | |

| Tensile Strength | 8KGS |

| Filter fineness | 5-50(μm) |

| Filter area | 100(m2) |

| OEM | Logo, Size and Shape of fiberglass filter bag, according to customer's requirement, and also drawing or samples. |

| Certificate | SDS |

| ISO9001:2015 |

Apply to filter and evenly distribute molten aluminum in molds.

Functions:

● Helps to reduce the turbulence of metal flow and improve the temperature distribution throughout the mold volume.

● Filter the molten metal and decrease in non-metallic inclusions and oxide films in the liquid metal.

● Improve mechanical quality of aluminum casting product.

● Improve the hardness of aluminum casting product with more average surface hard and bending strength.

Comparing to other filter bags, it does not affect the component of aluminum alloy, and with good filtration effect, high temperature resistance, high strength, excellent acid and alkali resistance, non-stick aluminum, non-slagging, non-peeling, as well as easy installation.

The Benefit of Fiberglass Filtration Shunt Combo Bag Used for casting filtration:

● Fiberglass Filtration Shunt Combo Bag is used in sand casting, permanent mold, shell mold, draw mold and investment casting, which can remove impurities, reduce turbulence, eliminate air bubbles, thereby improve casting quality and reduce production costs.

● At the same time, the shunt bag does not pollute the liquid aluminum, does not affect the chemical properties of the metal, and the aluminium liquid can be directly remelt, thus the cost can be reduced greatly.

● The bag can withstand the liquid temperature of 700℃, it can be used continuously for 4 hours when the flow is not more than 10 kg/min, for 1.5 hours continuously when not more than 120 kg/min.

● It can ensure the removal of oxides or other debris suspended in the volume, remove the harmful impurities such as bubbles, ash oxides, and various inclusions in aluminum molten liquid, greatly improve the yield of aluminum castings, improve the quality of aluminum products, and avoid the problem of other metal components into aluminum solution, does not affect the composition of aluminum alloy, to ensure the quality of aluminum castings.

● It is the ideal filtration material in the process of aluminum metal smelting.

● This bag can also improve the mechanical properties of aluminum castings, can increase the hardness of the castings, and the surface hardness is uniform and improve the bending strength of the castings. In this way, the manufacturer can produce terminal products with assured quality.

All dimensions can be customized according to your drawing, pictures and samples!