Tungsten Carbide Rods with 30/40 degree 2 Helical Coolant Holes

The carbide rod has a grain size of 0.5 µm and a cobalt content of 12% ensures that it has ultra-high toughness and high hardness. In addition to hole processing and thread processing, the tungsten carbide rod is particularly suitable for milling titanium alloys, heat-resistant alloys, gray cast iron, stainless steel, hardened stee Tungsten Carbide Rods with two 30 degree/40 degree helix holes.

Product Description

Product Specification

|

Product name |

330mm Tungsten Carbide Rods with 30/40 degree 2 Helical Coolant Holes |

|

Brand |

JIMS |

|

Appllication |

For cutting ,milling,and drilling |

|

Material |

WC+CO |

|

Hardness |

≥90.5HRA |

|

Length |

330mm or customized |

|

Grades |

YG10X/JF20 |

Our tungsten carbide rods includes:

1. Tungsten Carbide Rods without holes.

2. Tungsten Carbide Rods with one straight holes.

3. Tungsten Carbide Rods with two straight holes.

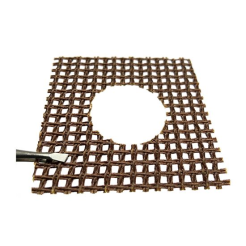

4. Tungsten Carbide Rods with two 30 degree/40 degree helix holes.

CARBIDE RODS PARAMETERS TABLE

|

Grade |

WC (μm) |

Co(%) |

Density (g/cm³) |

Hardness (HRA) |

TRS (N/m㎡) |

Recommended Use |

|

JU06 |

<0.6 |

6 |

14.75 |

94.0 |

3600 |

Composite Machining

|

|

JF15 |

0.8 |

10 |

14.38 |

92.2 |

3900 |

Stainless Steel, Cast Iron, Titanium Alloy Machining |

|

JF20 |

0.6 |

10 |

14.45 |

92.3 |

4000 |

Stainless Steel, Cast Iron, Titanium Alloy Machining |

|

JF25 |

0.6 |

12 |

14.10 |

92.5 |

4000 |

Stainless Steel, Cast Iron, Titanium Alloy Machining |

|

JF35 |

<0.6 |

12 |

14.05 |

92.8 |

4100 |

Stainless Steel, Cast Iron, Titanium Alloy Machining |

|

YG10X |

0.8 |

10 |

14.35 |

91.2 |

3600 |

Steel,Cast Iron, Non-Ferrous Metal, Titanium Alloy Machining |

| Type | Diameter | T ol. | Length | Diameter | T ol. | TK | T ol. | A | Pitch | Tol |

| Bφ6×2φ0.7×2.6×330H30 | 6 | +0.7,+1.3 | 330 | 0.70 | ±0.10 | 2.60 | 0,-0.4 | 0.15 | 32.65 | +0.67,-0.65 |

| Bφ7×2φ1.0×3.7×330H30 | 7 | +0.7,+1.3 | 330 | 1.00 | ±0.15 | 3.70 | 0,-0.4 | 0.15 | 38.09 | +0.78,,-0.76 |

| Bφ8×2φ1.0×4.0×330H30 | 8 | +0.7,+1.3 | 330 | 1.00 | ±0.15 | 4.00 | 0,-0.4 | 0.15 | 43.53 | +0.89,-0.86 |

| Bφ9×2φ1.4×4.8×330H30 | 9 | +0.7,+1.3 | 330 | 1.40 | ±0.15 | 4.80 | 0,-0.6 | 0.20 | 48.97 | +1.00,-0.97 |

| Bφ10×2φ1.4×4.8×330H30 | 10 | +0.7,+1.3 | 330 | 1.40 | ±0.15 | 4.80 | 0,-0.6 | 0.20 | 54.41 | +1.11,-0.97 |

| Bφ11×2φ1.4×5.3×330H30 | 11 | +0.7,+1.4 | 330 | 1.40 | ±0.15 | 5.30 | 0,-0.8 | 0.30 | 59.86 | +1.22,-1.19 |

| Bφ12×2φ1.4×6.25×330H30 | 12 | +0.7,+1.4 | 330 | 1.40 | ±0.15 | 6.25 | 0,-0.8 | 0.30 | 65.30 | +1.34,-1.30 |

| Bφ13×2φ1.75×6.5×330H30 | 13 | +0.7,+1.4 | 330 | 1.75 | ±0.20 | 6.50 | 0,-0.8 | 0.37 | 70.74 | +1.45,-1.40 |

| Bφ14×2φ1.75×7.1×330H30 | 14 | +0.7,+1.5 | 330 | 1.75 | ±0.20 | 7.10 | 0,-0.8 | 0.40 | 76.18 | +1.56,-1.51 |

| Bφ15×2φ1.75×7.7×330H30 | 15 | +0.7,+1.5 | 330 | 1.75 | ±0.20 | 7.70 | 0,-0.8 | 0.40 | 81.62 | +1.67,-1.62 |

| Bφ16×2φ1.75×8.3×330H30 | 16 | +0.7,+1.6 | 330 | 1.75 | ±0.20 | 8.30 | 0,-0.8 | 0.40 | 87.06 | +1.78,-1.83 |

| Bφ17×2φ1.75×8.9×330H30 | 17 | +0.7,+1.6 | 330 | 1.75 | ±0.20 | 8.90 | 0,-0.8 | 0.45 | 92.50 | +1.89,-1.84 |

| Bφ18×2φ2.3×9.55×330H30 | 18 | +0.7,+1.7 | 330 | 2.30 | ±0.25 | 9.55 | 0,-0.8 | 0.50 | 97.95 | +2.00,-1.94 |

| Bφ19×2φ2.3×10.1×330H30 | 19 | +0.7,+1.7 | 330 | 2.30 | ±0.25 | 10.10 | 0,-0.8 | 0.50 | 103.39 | +2.12,-2.05 |

| Bφ20×2φ2.5×10.4×330H30 | 20 | +0.7,+1.7 | 330 | 2.5 | ±0.25 | 10.40 | 0,-1.0 | 0.50 | 108.83 | +2.23,-2.16 |

Product Process

Note: Can offer customized product based on customer requirements.