Pot bearings (Passenger-dedicated Railway) (CPPD)

Best price rubber pot bearing for railway with 24 levels of vertical bearing capacity. When it is more than 50000KN, the pot bearing can be designed separately

Product Description

Pot bearings, also known as rubber pot bearings, can be divided into fixed pot bearings, guided pot bearings and free sliding pot bearings. Rubber pot bearings are special types of bridge bearings used to withstand large loads, large horizontal displacements and large rotation requirements in narrow areas of bridges. Compared with elastic supports, pot supports have greater load-bearing capacity.

Technical performance

1. There are 24 levels of vertical bearing capacity: The capacity range from 2500KN to 50000KN.

When the vertical bearing capacity is more than 50000KN, it can be designed separately.

2. The design angle of the bearing is not less than 0.02rad

3. The design horizontal force of the fixed bearing, the longitudinal movable bearing in the transverse bridge direction, and the transverse movable bearing along the bridge direction is 15%, 20%, 30%, 40% of the vertical design bearing capacity of the bearings:

● 15%-In the area with acceleration of peak ground motion is Ag ≤ 0.1g

● 20%-In the area with acceleration of peak ground motion is 0.1g<Ag≤0.15g

● 30%-In the area with acceleration of peak ground motion is 0.15g<Ag≤0.2g

● 40%-In the area with acceleration of peak ground motion is 0.2g<Ag≤0.3g

The design horizontal force of the two way movable bearing in each direction, the longitudinal movable bearing along the bridge direction and the horizontal movable bearing in the transverse direction is 5% of the vertical design bearing capacity of the bearing.

4. Displacement and structure

Design displacement along the bridge direction of multidirectional movable bearing and longitudinal movable bearing are ±50mm, ±100mm, ±150mm, ±200mm, ±250mm.

multidirectional movable bearing

5. Design friction coefficient of bearing: the design friction coefficient of movable bearing with silicone grease lubrication:

● Normal temperature type μ≤ 0.03,

● Cold resistant type μ ≤0.05.

6. Applicable range of temperature:

● Normal temperature type -25℃~+60℃ adopts neoprene or natural rubber;

● Cold-resistant type -40℃~+60℃ adopts EPDM or natural rubber.

7. Height adjustment of railway pot bearing:

The length of bolts of CPPD pot rubber bearing is reserved, and lifting jack is required for height adjustment.

Railway pot bearing types

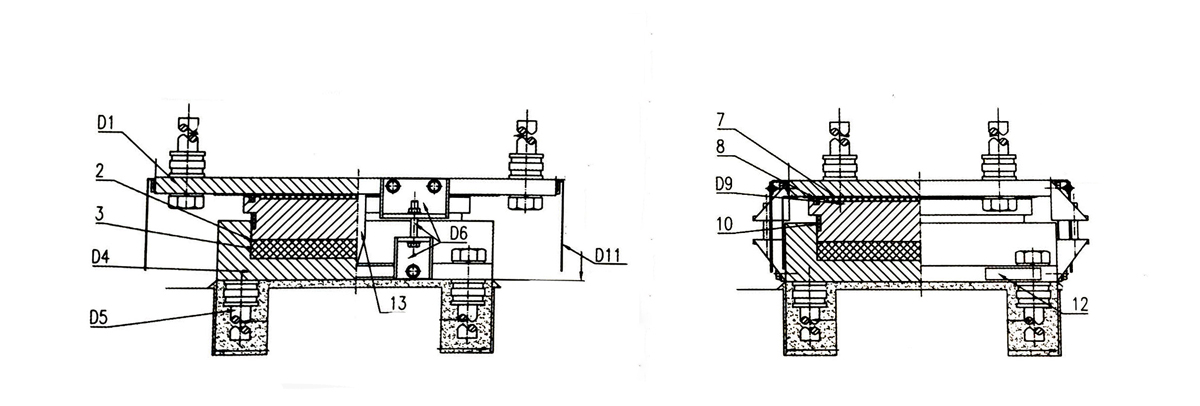

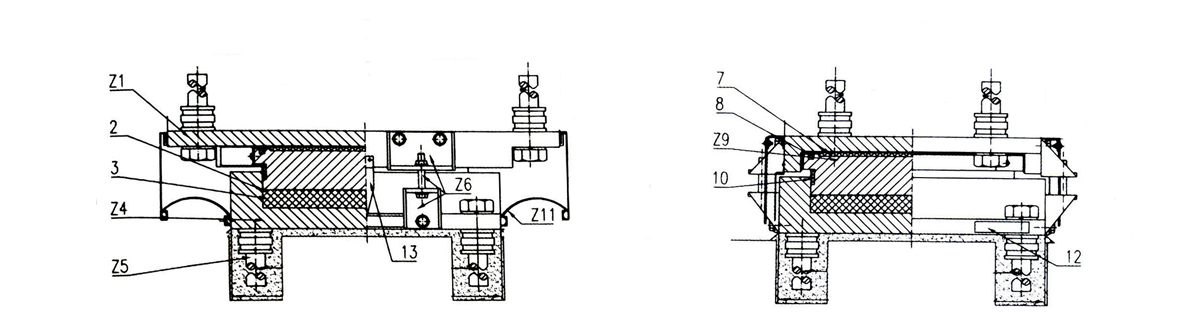

1. Fixed pot bearing

Fixed pot bearings do not move in all directions. Under load, the elastomeric bearing pad behaves like an incompressible confined fluid that can rotate on any axis.

2. Guide pot bearing

Guided pan bearings with steel guide edges can only move in one direction. Stainless steel slides and PTFE slides further reduce the coefficient of friction and allow for relatively small horizontal loads.

3. Free sliding pot bearing

Bearing assemblies have been added between the piston and base plate, the free-sliding pan bearings can move in all directions.

Features of rubber pot bearing for railway:

1. New structural design

The fixed support adopts tenon and mortise structure, which can evenly transmit the horizontal force to any direction. The one-way sliding guide bearing improves the sliding guide performance of the bearing.

2. Reliable material quality

The steel of the pot bearings for bridges adopts hot-rolled steel plate, which improves the overall force performance of the bearing. All metal parts are protected from corrosion by galvanizing and epoxy painting. High-quality materials effectively reduce the bearing's structural size, weight and cost.

3. Easy to install

The mechanical pot bearing is connected with the piers and beams by sleeves and anchor bolts. Construction, installation and replacement are convenient.

Yongxi rubber pot bearing for railway and Seismic lsolations improves the bearing capacity and performance, prolong the service life, and reduce the structural size, weight and cost of pot bearings for bridges. It is a new type of bridge component that meets domestic and foreign double standards and multiple specifications. For pot bearing details, please feel free to contact us!

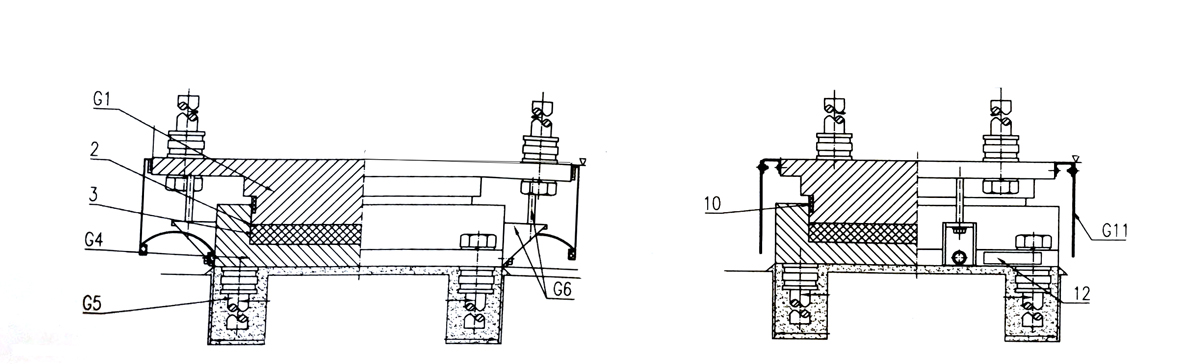

The elevation process is as follows:

1). In case of uneven downpunching of the foundation, the height adjustment amount of the pot bearing shall be determined through measurement, and the jack layout scheme during height adjustment and the allowable jacking height of the beam body shall be formulated.

2). This series of pot bearings are raised by padded steel plate (The padded steel plate can be placed between the top upper plate of pot bearing and the beam bottom, or between the bottom plate of the pot bearing and the pad stone.)It is preferred to add a steel base plate between the top upper plate of pot bearing and the beam bottom.

3). According to the size of the pot bearing and the height of the adjustment required, then process the steel base plate for height adjustment.

4). Install temporary supports or force jacks on the top of the pedestal and pier that need to be raised, and connect the oil circuit.

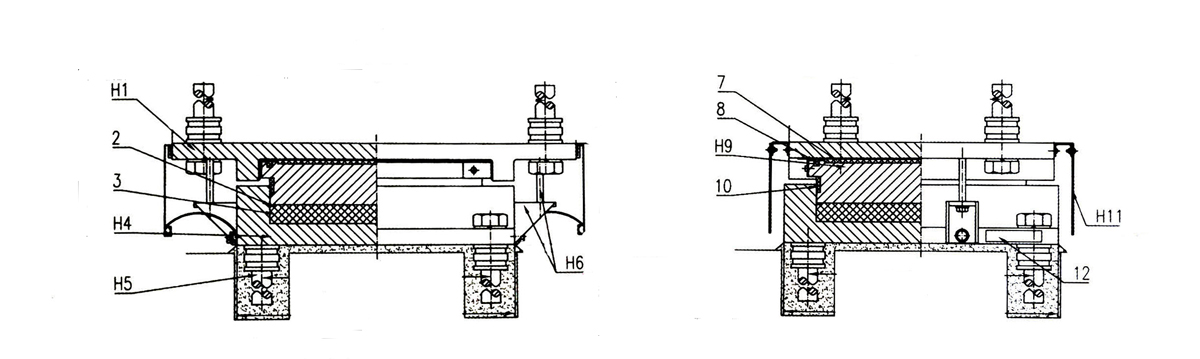

5). Screw out the anchor bolt on the support (between the top of the upper seat plate and the bottom of the beam when raising the plate) or the anchor bolt (between the bottom of the lower seat plate and the top of the stone when raising the plate). Screw on the pot bearing anchor bolts, but do not tighten them.

6). The top beam is 1~3mm higher than the required adjustment height, insert the elevation steel plate (when the plate is added between the bottom of the seat plate and the top of the cushion stone, the lower plate of pot bearing needs to be lifted with the bearing connecting steel plate and the connecting bolt), screw the bearing anchor bolt, but not tighten.

7). Oil pump returns to pressure the bearing, tighten the anchor bolts of the bearing, and remove the jack.

8). Check the position of the pot bearing, plug the gap between the pot bearing and the steel plate, and paint for protection. The height adjustment of pot bearing is completed.

In the process of the above height of adjustment, if manual pressure is used for the thin hydraulic cylinder or force jack, the jacking reaction difference of the two fulcrum at the same beam end should be controlled within 5%, and the oil circuit of the thin hydraulic cylinder or force jack at the two fulcrum at the same beam end should be connected.