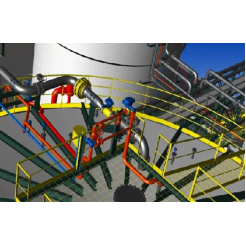

Electrical Tracing on Pipe

Electrical tracing, also known as heat tracing or electric heat tracing, is a method used to prevent freezing or maintain a specific temperature in pipes, vessels, or equipment that carry or store liquids or gases.

Product Description

Electrical tracing, also known as heat tracing or electric heat tracing, is a method used to prevent freezing or maintain a specific temperature in pipes, vessels, or equipment that carry or store liquids or gases. It involves the installation of electrical heating elements along the length of the pipe to provide heat as needed.

Electrical tracing on pipes is a versatile solution for maintaining temperatures in various industrial and commercial applications. It is commonly used in industries such as petrochemical, food processing, and utilities, as well as for residential purposes in cold climates. Proper design, installation, and maintenance are critical to the safe and efficient operation of electrical tracing systems.

Purpose of Electrical Tracing:

Electrical tracing is typically used in situations where it's essential to maintain the temperature of the contents within a pipe or prevent the pipe from freezing. Common applications include:

-

Process heating in industrial systems.

-

Freeze protection in cold climates for water pipes, sprinkler systems, and outdoor equipment.

-

Temperature maintenance for pipelines carrying temperature-sensitive fluids, such as chemicals or food products.

Types of Electrical Tracing:

There are two main types of electrical tracing:

-

Self-regulating heating cables: These cables automatically adjust their heat output based on the temperature of the pipe. They are energy-efficient and less likely to overheat.

-

Constant wattage heating cables: These cables provide a consistent amount of heat output and are suitable for applications where a steady heat supply is required.