16GA Black Annealed Iron wire Binding Wire

Black iron wire has good elasticity and flexibility, which can control its softness and hardness during the annealing process. It is made of high-quality iron wire and is mainly used in the construction industry as binding wire and wire.

Product Description

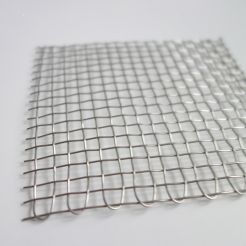

16GA Black Annealed Iron wire Binding Wire

Black annealed wire is also called black iron wire,soft annealed wire and annealed iron wire.It includes annealed wire and black oiled wire.Annealed wire is obtained by means of thermal annealing. It’s made of carbon steel wire. Annealed wire offers excellent flexibility and softness through the process of oxygen free annealing. And the black oiled wire is formed via the process of wire-drawing, anneal, and fuel oil injection. Production process:The hot metal billet is rolled into steel bar, that is, wire rod, and then put it into the wire drawing device to draw wires with different diameters, gradually reduce the aperture of the wire drawing disc, and carry out cooling, annealing,plating and other processing processes to make iron wires of different specifications. It contains iron, cobalt, nickel, copper,carbon, zinc and other elements.

|

SPECIFICATIONS FOR BLACK ANNEALED WILE |

|||

|

Wire Gauge Size |

SWG(mm ) |

BWG(mm) |

BG(mm) |

|

6 |

4.87 |

5.15 |

5.03 |

|

7 |

4.47 |

4.57 |

4.48 |

|

8 |

4.06 |

4.17 |

3.98 |

|

9 |

3.66 |

3.76 |

3.55 |

|

10 |

3.25 |

3.40 |

3.17 |

|

11 |

2.94 |

3.05 |

2.82 |

|

12 |

2.64 |

2.77 |

2.51 |

|

13 |

2.33 |

2.41 |

2.24 |

|

14 |

2.03 |

2.11 |

1.99 |

|

15 |

1.83 |

1.83 |

1.77 |

|

16 |

1.62 |

1.65 |

1.58 |

|

17 |

1.42 |

1.47 |

1.41 |

|

18 |

1.22 |

1.24 |

1.25 |

|

19 |

1.01 |

1.06 |

1.11 |

|

20 |

0.91 |

0.88 |

0.99 |

|

21 |

0.81 |

0.81 |

0.88 |

|

22 |

0.71 |

0.71 |

0.79 |

Production method

There are two kinds of drawing machine: powder drawing and water drawing. powder drawing is fit for junior drawing(6.5mm~4.0mm). One powder drawing machine has 4 tanks and 4 molds. One tank is matched with a mold. Each of them are offered energy by a electromotor. 0.9mm(max)can be “eat” when the wire cross a mold. There are no loss of weight during drawing. Anneal is to low the tensile strength of wire. The stove is solid and built with red bricks. The architecture of anneal stove is cuboid. Different thickness of wire require different temperature. Range is from 700℃to 900℃. Output of the anneal stove, the tensile strength is 400N~500N.

Package and Delivery

(1)Deliver by sea to normal sea ports in full containers available, also accept LCL shipping.

(2)Deliver by air, by rail also acceptable.

(3)Packing: plastic parts packed with PP film and bubble bags outside, steel parts packed in cotton and cartons.

Features

· Various weights and dimensions.

· Excellent flexibility and softness.

· Bright and smooth surface.

· Anti-corrosion and anti-oxidation.

· Long service life.

Email: info@bxmeshwire.cn

Mob.: +86 189 4263 6963

WeChat: baozi0825min

Skype: colin1314@outlook.com

Whatsapp: +8618942636963

Add.: Room 412, Building 7, Baoneng Center, Zhengding New District, Zhengding Area of China (Hebei) Pilot Free Trade Zone