black annealed binding wire tying wire

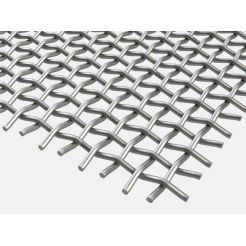

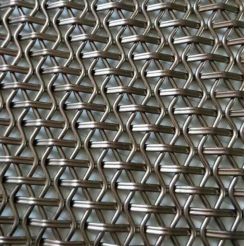

Black iron wire has good elasticity and flexibility, which can control its softness and hardness during the annealing process. It is made of high-quality iron wire and is mainly used in the construction industry as binding wire and wire.

Product Description

black annealed binding wire tying wire

Black annealed wire is also called black iron wire, soft annealed wire and annealed iron wire. The main wire material of black annealed wire is iron wire or carbon steel wire. Black Annealed Wire is deployed both in construction and in agriculture. In civil construction annealed wire, also known as 'burnt wire' is used for iron setting. In agriculture annealed wire is used for bailing hay. Meantime black annealed wire is widely used as tie wire or baling wire in building, parks and daily binding. Black annealed wire is mainly processed into coil wire, spool wire, big package wire or further straightened and cut into cut wire and U type wire. Annealed wire offers excellent flexibility and softness through the process of oxygen free annealing. And the black oiled wire is formed via the process of wire-drawing, anneal, and fuel oil injection. We can do it into straight cutting wire and also do according to customers' special requirement.

|

Wire Gauge |

SWG in mm |

BWG in mm |

In Metric System mm |

|

8# |

4.06 |

4.19 |

4.00 |

|

9# |

3.66 |

3.76 |

- |

|

10# |

3.25 |

3.40 |

3.50 |

|

11# |

2.95 |

3.05 |

3.00 |

|

12# |

2.64 |

2.77 |

2.80 |

|

13# |

2.34 |

2.41 |

2.50 |

|

14# |

2.03 |

2.11 |

- |

|

15# |

1.83 |

1.83 |

1.80 |

|

16# |

1.63 |

1.65 |

1.65 |

|

17# |

1.42 |

1.47 |

1.40 |

|

18# |

1.22 |

1.25 |

1.20 |

|

19# |

1.02 |

1.07 |

1.00 |

|

20# |

0.91 |

0.89 |

0.90 |

|

21# |

0.81 |

0.813 |

0.80 |

|

22# |

0.71 |

0.711 |

0.70 |

Production method

There are two kinds of drawing machine: powder drawing and water drawing. powder drawing is fit for junior drawing(6.5mm~4.0mm). One powder drawing machine has 4 tanks and 4 molds. One tank is matched with a mold. Each of them are offered energy by a electromotor. 0.9mm(max)can be “eat” when the wire cross a mold. There are no loss of weight during drawing. Anneal is to low the tensile strength of wire. The stove is solid and built with red bricks. The architecture of anneal stove is cuboid. Different thickness of wire require different temperature. Range is from 700℃to 900℃. Output of the anneal stove, the tensile strength is 400N~500N.

Package:

Each roll wrapped by hessain cloth or woven bag/ several rolls bundle or pallets

Features

· Various weights and dimensions.

· Excellent flexibility and softness.

· Bright and smooth surface.

· Anti-corrosion and anti-oxidation.

· Long service life.

Email: info@bxmeshwire.cn

Mob.: +86 189 4263 6963

WeChat: baozi0825min

Skype: colin1314@outlook.com

Whatsapp: +8618942636963

Add.: Room 412, Building 7, Baoneng Center, Zhengding New District, Zhengding Area of China (Hebei) Pilot Free Trade Zone