Puff Snacks Extruding Machine

Puff Snacks Processing Line can process various direct cereal based snackswith a wide variety of recipes and shapes.

Product Description

Puff Snacks Extruding Machine

Puff Snacks Processing Line can process various direct cereal based snackswith a wide variety of recipes and shapes.

Food Extruder Machine makes it possible for automation of food through a continuous, reliable system that ensures harmony of the end product. Food produced using a food extrusion machine normally has a high starch content. These include some pasta, breads (croutons, bread sticks, and also flat breads), several morning meal cereals and also ready-to-eat treats, confectionery, pre-made cookie dough, some infant foods, full-fat soy, distinctive vegetable protein, some drinks, and completely dry and semi-moist animal foods.

The advantages of the Snack Food Extruder Machine

- High productivity food extrusion machine: remarkable process-enhanced capability of twin screw food extrusion machine and also related process allows work advantage to be attained, for instance, continuous HTST processing, greater effectiveness because of decreasing cooling down time and also the account of component losses, power as well as water price lowered.

- Incredibly versatile food extrusion machine: the identical twin screw food extrusion machine has the ability to process various sorts of ingredient to make a number of surface products;

- Completely automated, with innovative operating protection; subsequently resulting in consistent producing the high quality extrusion food; while standard handling modern technology require duplicated adjusting of procedure variables.

- Significantly suitable for new item growth, with the chance to focus on quickly the attributes of surface products that are flavor, savor, structure and nourishment.

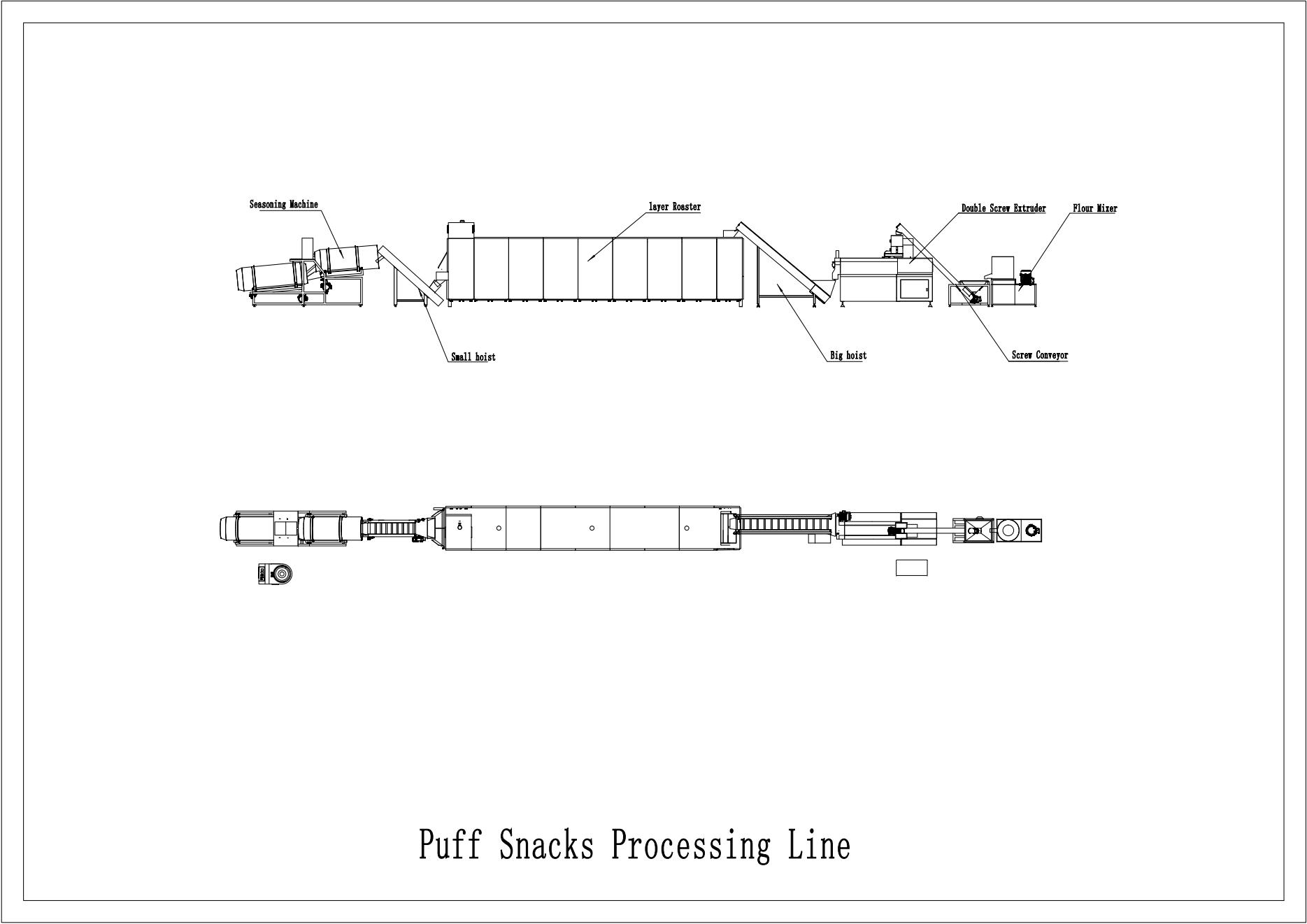

Flow Chart

Layout

Technical Features:

|

Model |

Capacity |

Power |

Dimension |

|

QL-65 |

120-150kg/hr |

52kw |

25 x 5 x 3m |

|

QL-70 |

200-300kg/hr |

86kw |

28 x 5 x 3m |

|

QL-85 |

500-800kg/hr |

140kw |

32 x 5 x 3m |